Spend-IT: Asian Paints bets on automation and digitalisation

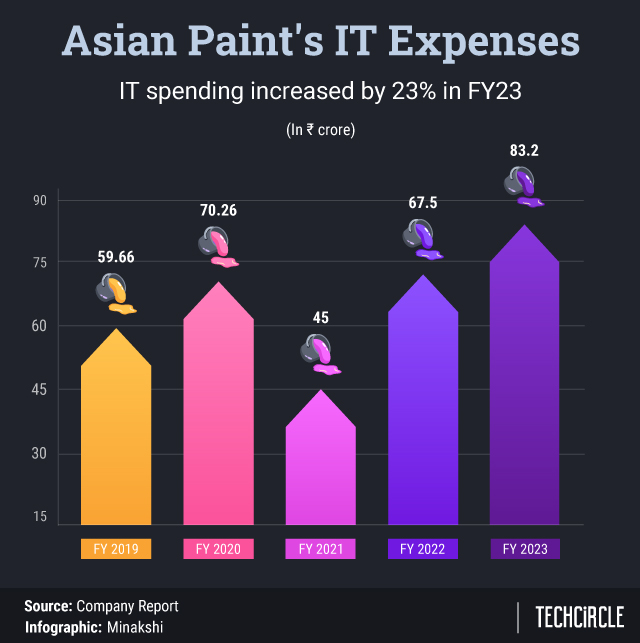

India’s largest paints company Asian Paints that had seen its tech spends sink with the onset of the pandemic only to bounce back thereafter has put extra dough to boost its automation and digital transformation in the year ended March 2023.

The firm’s total tech budget rose by a quarter to shoot past the pre-pandemic high of ₹70 crore (in FY20) to hit ₹83.2 crore mark last year.

Asian Paints is leveraging emerging technologies like artificial intelligence (AI) to enhance collaboration, generate insights, improve efficiency, and enhance the customer experience. On the manufacturing side, the company is implementing automation and robotic technologies to boost efficiency and reduce waste.

Key areas such as paint mixing, packaging, and labeling have undergone automation, resulting in increased production output and a reduced environmental footprint. This optimisation of resources has allowed the company to divert its focus toward critical domains such as product development, innovation, and marketing, as highlighted in its annual report.

For FY23, Asian Paints outlined three main priorities: creating data lakes, utilising data analytics to understand changing customer preferences and establishing a technology framework for supply chain management. In FY22, the introduction of a control tower enhanced supply chain flexibility and agility. Further, this year Asian Paints plans on enhancing the approach with more focus on improving supply planning and reducing non-value-added activities.

Other initiatives include the company’s core transaction systems, which run on a range of enterprise resource planning (ERP) systems, including SAP S/4 HANA and SAP B1. These systems, which manage critical processes such as Order-to-Cash, Procure-to-Pay, Core Financial & Master Data, have been upgraded to the latest S/4HANA system version, expanding the footprint of digital processes within the organisation.

“Since the last few years, there has been a huge focus on crafting immersive and cutting-edge customer experiences across all customer points, with the intent of creating seamless, consistent, and personalised experiences for our customers all across through the usage of smart business insights developed through the implementation of analytical tools,” the company said.

To this end, employees are actively utilising AI and machine learning (ML) techniques, with the company setting its sights on becoming an Insight-Driven Organisation (IDO). Management intends to launch more AI/ML-based scenarios and enhance productivity through automated reporting.

AI in manufacturing is getting a lot of traction in the last few years. In fact, a study by market research firm MarketsandMarkets found that AI in the manufacturing market in terms of revenue will reach $16.3 billion in 2027.