Space startups turn to 3D printing to meet expected demand

Indian space technology startups, which are starting to put funds towards manufacturing facilities, are turning to 3D printers to achieve scale. For startups like IIT Madras-incubated Agnikul Cosmos, Hyderabad-based Skyroot Aerospace, Pixxel Space and more, 3D printers are going to help achieve initial scale before they can move towards traditional processes like injection molding.

While 3D printers will never help achieve industrial scale, executives from these firms said that their current production needs will be met using 3D printers.

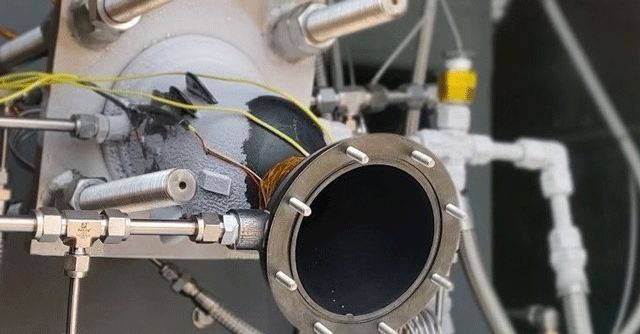

For instance, Agnikul Cosmos unveiled its own rocket engine facility in Chennai on July 13. Srinath Ravichandran, chief executive of Agnikul, told Mint that the company initially plans to fully 3D print two rocket engines every week, and a total of eight engines per month — all of which will be required to assemble its in-house launch vehicle, called Agnibaan.

Skyroot Aerospace, too, will use 3D printers to build rocket engines, Pawan Kumar Chandana, CEO of the firm, said. Presently the firm is partnering with manufacturing vendors in Bengaluru and Chennai who use 3D printers, but it plans to set up its own factory in future, according to Chandana.

The move towards 3D printing is significant in the context of the government’s upcoming space policy. As reported by Mint earlier, the policy will for the first time allow private space firms in India to run their own missions, increasing the need for these companies to manufacture their own products. The alternative, which is sourcing internationally, is expensive for Indian space firms, most of which are still early stage startups.

The model is also proven overseas. For instance, USA’s Rocket Lab builds its Capstone satellite using 3D printing. The Capstone Satellite will survey the lunar surface, building up to the 2024 manned mission, called Artemis, being planned by the National Aeronautics and Space Administration (NASA).

Its rocket, called Electron, is also a fully 3D printed rocket that has already flown to space 26 times since 2017, with an 88% success rate. Rockets like Agnikul’s Agnibaan are meant to be cheaper alternatives to rockets like Electron and SpaceX’s reusable Falcon 9 rocket.

“A rocket engine is a complicated machine, and building one typically requires hundreds of components. Such complications mean that if there is an engineering fault in any component within the engine, the percentage of error in the entire engine would rise, and so would its chances of failure. A 3D printed rocket engine, however, is one block built based on a design template, using aerospace grade metals – which therefore drastically reduces the chances of error in these engines,” Skyroot’s Chandana said.

Other than Agnikul and Skyroot, Bengaluru-based Dhruva Space and Pixxel are also using 3D printing to build their satellites. While Dhruva aims to offer satellite manufacturing as a service to global companies eventually, Pixxel uses 3D printing to build components for its own satellites. Skyroot’s Chandana said that 3D printing helped produce its first rocket engine in two days, as opposed to hundreds of hours that traditional manufacturing processes would have taken. Agnikul’s factory can produce a full rocket in 72 hours, the company claims.

Anil Prakash, director general of industry body Satellite Industry Association of India (SIA), said that over 60,000 privately operated satellites are expected to be launched globally in the next five years. “If India can build capacity, it can attract a wider number of clients and grow its share of the international space economy,” he said.

“Our space sector may take another five years to reach the maturity of the US or France, but adding capacity now will help private companies scale their operations, once we get there,” said Anupam Shukla, a space sector lawyer and partner at Pioneer Legal.